Automated welding equipment is an inexpensive, modular building block family of portable machines, which provide precise path and constant speed control in any plane or position. Ingenious users solve fabricating problems with standard, interchangeable components at a fraction of the cost of custom designed machines or robots.

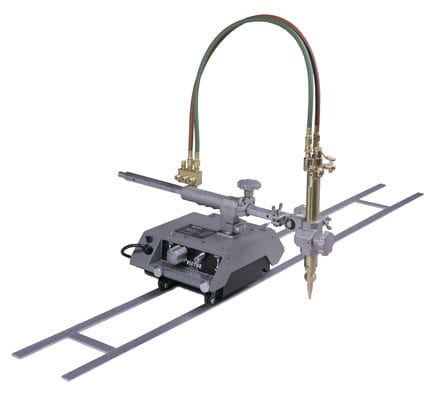

Bug-O System VS Manual Welder