Industrial Gas Supply

Your Trusted Industrial Gas Supplier

Industrial gasses are not a one-size-fits-all solution.Toll Gas understands the essentials of securing a reliable supplier, managing costs, and maintaining consistent quality.

- Full-Service Delivery

- 24hr On-Call Service

- High Pressure Cylinders

- Low Pressure Cylinders

- Cryogenic Dewars

- Bulk Tanks

Industrial Gas Supply Quote

- Industrial, Medical & Specialty Gases

- Locally Owned & Operated

Our Bulk Gasses Offering

Our bulk gasses offering includes a wide range of gasses suitable for diverse applications. Some of our key bulk gasses include:

Acetylene

Acetylene

Acetylene (C2H2) is an explosive gas which in the presence of the right amount of oxygen burns with a brilliant flame at a temperature of about 3000°C.

Air

Air

Air is a colorless, odorless, nonflammable gas. Industrial air is used in air carbon arc gouging and in plasma arc cutting (PAC) processes.

Carbon Dioxide

Carbon Dioxide

Carbon Dioxide (CO2) is a tasteless, colorless, odorless, nonflammable gas.

Helium

Helium

Helium (He) is the second lightest elemental gas next to hydrogen. Colorless, odorless, tasteless, nontoxic and chemically inert, helium is nonflammable and has a high thermal conductivity.

Hydrogen

Hydrogen

The reducing properties of Hydrogen (H2) are used to remove oxygen during high-temperature processes such as metal treatment or float glass production.

Nitrogen

Nitrogen

Nitrogen (N2) has applications in a wide range of industries, including the chemical, pharmaceutical, petroleum, glass and ceramic manufacturing, metal, pulp and paper manufacturing, and in healthcare.

Oxygen

Oxygen

Oxygen (O2) is commonly used, with or instead of air, to increase the amount of oxygen available for combustion or biological activity.

Propane

Propane

Propane (C3H8) is a colorless, flammable, liquefied gas with a natural gas odor.

Propylene

Propylene

Propylene (C3H6) is a colorless, flammable, liquefied gas with a faintly sweet odor.

Ensuring Uninterrupted Gas Supply

Having a reliable industrial gas supplier is only half the battle won. The other half lies in ensuring a consistent and uninterrupted supply of these gases. This is where suppliers with a wide geographical reach and a robust network come into play. Toll Gas guarantees continuous delivery to multiple regions.

Absolute Air Plant

In 2022 we launched our state-of-the-art Absolute Air plant so we can meet the highest standards of quality, affordability and customer service. Our new plant offer gasses for a huge range of industries from medical gasses, industrial gasses to food service and scientific gasses. The facility meets and exceeds the most rigorous industry criteria and safety certifications.

Specialty Gases for Advanced Applications

Specialty gasses are at the heart of many advanced manufacturing processes. These high-quality gas mixtures are tailored for specific, precision-driven applications, making them indispensable to the manufacturing industry. Clean energy sources, these gases leave no residue, a vital characteristic for industries such as electronics and pharmaceuticals where contamination control is paramount.

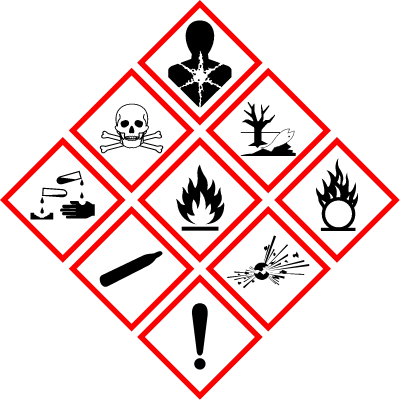

Industrial Gas Supply Safety

At Toll Gas safety is our number one priority. Toll Company follows the stringest safety protocols and offers Safety Data Sheets for all our products. Safety always comes first for our employees and we want to help you communicate the same priority to your employees.

The safe handling and storage of industrial gasses require awareness of potential risks, appropriate safety equipment, and regular training to prevent accidents. Toll Gas also offers a variety of safety training programs to help educate your workforce on the latest regulations, requirements and best practices.

The Toll Gas Difference

At Toll Gas we are a 100% employee owned gas and welding distributor headquartered in Plymouth, MN. This means you are working with an owner of the company every time you contact us. As owners, our people are empowered to make decisions and do what they believe is right and best to service your needs. We are proud to be serving our clients for over 75 years.

Frequently Asked Industrial Gas Questions

Common industrial gases include oxygen, nitrogen, hydrogen, helium, argon, carbon dioxide, and acetylene, among others.

Industrial gases are usually stored in high-pressure cylinders, cryogenic tanks, or delivered via bulk liquid tanker trucks or pipelines.

Safety measures include proper training for personnel, adherence to regulatory guidelines, regular equipment maintenance, and the use of appropriate protective gear.

Outsourcing industrial gas supply ensures reliable access to high-quality gases, eliminates the need for large capital investment in gas storage infrastructure, and allows businesses to focus on their core operations.

By partnering with reputable suppliers who offer reliable delivery schedules, robust logistics capabilities, and emergency response protocols.

Factors such as market demand, production costs, transportation expenses, and regulatory compliance requirements can impact the pricing of industrial gases.

By conducting thorough assessments of their production processes, analyzing consumption patterns, and consulting with gas supply experts.

Environmental considerations include minimizing greenhouse gas emissions during production and transportation, optimizing gas usage efficiency, and adhering to regulatory standards for emissions control.

Yes, many industrial gas suppliers offer services such as equipment installation, maintenance, and training to ensure safe and efficient gas handling.

High-quality industrial gases are essential for maintaining product quality, ensuring process efficiency, and minimizing the risk of equipment malfunction or contamination.

Industrial gases are primarily used in manufacturing, welding, and other industrial processes, whereas medical-grade gases are specially purified and used in healthcare settings for patient treatment and life support.

By implementing gas monitoring systems, optimizing process parameters, minimizing gas wastage, and exploring opportunities for gas recycling or recovery.

Bulk delivery systems offer cost savings through economies of scale, reduced handling and storage requirements, and increased operational efficiency.

Regulatory standards govern various aspects of industrial gas production, transportation, storage, and usage to ensure safety, environmental protection, and product quality.

Yes, many industrial gas suppliers offer customized gas blends tailored to meet the unique requirements of specific industrial processes or applications.

Gas supply interruptions can disrupt production schedules, lead to costly downtime, and impact product quality, emphasizing the importance of reliable supply chain management.

Advancements in gas production technology lead to improvements in efficiency, cost-effectiveness, and environmental sustainability, driving innovation within the industrial gas supply industry.

Considerations include the supplier’s reliability, safety record, product quality, technical support capabilities, and alignment with the business’s sustainability goals.

Industrial gas suppliers invest in regulatory compliance programs, conduct regular audits, and maintain documentation to demonstrate adherence to applicable laws and standards.

Industrial gas suppliers play a crucial role by offering eco-friendly gas production processes, promoting gas recycling and reuse initiatives, and assisting customers in reducing their carbon footprint through efficient gas usage practices.

Need Help With Industrial

Gas Supply?

We offer industriall facility services and support

and can quickly address onsite issues, has made us

a top-rated supplier in the medical field.